Same Day Service

Since 2002

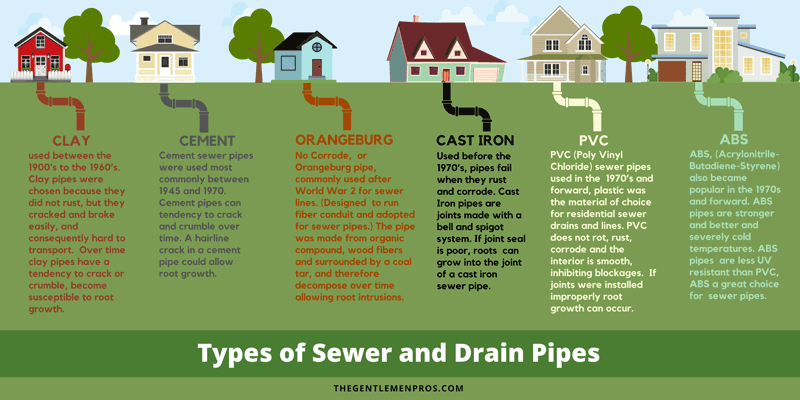

This article will explain the types of sewer pipes that were used in Alberta over the last 100 years, and explain the pitfalls of each pipe.

Sewer backups happen when your main sewer line is clogged. A sewer backup is when sewage returns back to your home through the lowest point, floor drain, toilet, or shower drain in the basement.

Most often sewer lines problems are a result of older failing pipes.

Sewer backups are disgusting and can do a lot of damage to your home. (Picture your basement flooded with sewage water.) Gross! 💩💩💩💩💩

A sewer backup indicates there is something wrong with your main sewer line. Most often the cause of a backup is because of aging or failing sewer pipes.

Schedule a sewer pipe camera inspection (link to other camera inspection Calgary) to ensure your pipes are flowing and free of deterioration and clogs. If you are buying a house, be sure to do a sewer line camera inspection(link to camera inspection Edmonton), during the home inspection stage of your purchase.

Read on to learn more!

It’s important to understand the pitfalls and lifespan of each type of sewer pipe.

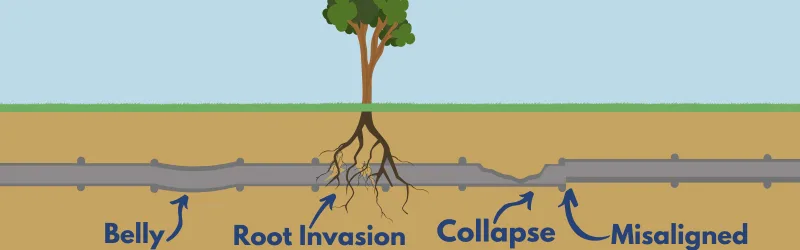

A pipe belly occurs when the pipe sags.

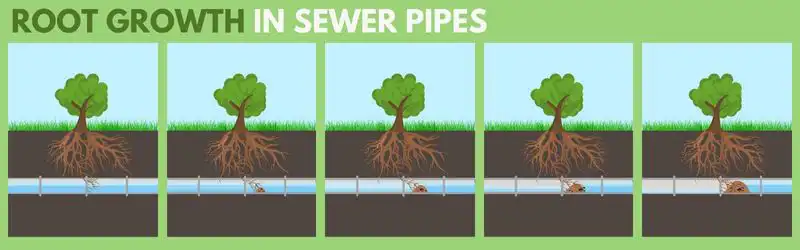

Roots can enter even the smallest crack in a sewer pipe.

Sewer pipes can collapse, and not allow sewage to pass through.

Misalignments can cause leaks, and prevent waste from moving through the pipes.

Clay sewer pipes were commonly used from the 1900s until the 1970s when they were phased out, in preference for plastic. Clay was a material of choice for sewer pipes because it did not rust. Clay pipes could be difficult to transport, and would often crack or break in the process. Clay pipes can withstand high levels of downward force without breaking.

Clay sewer pipes usually will last 50 to 60 years. Joints are typically the first thing to go, which often leads to root growth or misalignments. Clay sewer pipes can crack, and crumble which can lead to full collapse.

Clay pipes were used throughout Alberta. Medicine Hat had a large clay industry, which is now a historical site.

In the early 1900s, clay industries resided in what is now the Calgary area and produced clay pipes.

Commonly used up until the 1970s. Cast iron sewer pipes fail when they rust and corrode.

Castrion sewer pipes typically corrode from the inside out, making the interior walls uneven. The uneven walls, cause waste to catch. This leads to clogs, as the pipe builds up with waste and debris.

Cast Iron pipe joints were made with a bell and spigot system, and over time the seals on the joints break down. (The quality of the joint was dependent on the person installing it.)

When the pipe joint breaks down, the pipes leak and are susceptible to root intrusions.

No-Corrode pipe or Orangeburg pipe (named after the manufacturer) was made from wood fibres and surrounded by coal tar.

Best described as a coal tar-impregnated toilet paper tube, these sewer pipes are a disaster waiting to happen.

Why did No-Corrode Pipe, Orangeburg Pipe or Black Pipe become a build choice? Price!

The no-corrode pipe gained popularity in the post-war baby boom, as demand for building supplies skyrocketed. Cast iron, the common material for sewer pipes, was in low supply during the post-war era.

Initially, no-corrode was designed for electrical lines and phone lines, but was later adopted for sewer lines.

Because the wood fibres and tar are organic compounds, over time the pipe breaks down. The pipe no longer holds a round shape as it becomes “soggy” and collapses. As the pipe breaks down it allows root growth and is often the cause of major sewer backups.

No corrode has a history of collapsing and breaking down before the projected 50-year life span.

Between 1940 and 1960 galvanized steel pipes were commonly used. Coated in zinc to prevent corrosion, the pipes have a life expectancy of about 50 years.

Over time as the zinc coating breaks down. Galvanized sewer pipes rust from the inside out, decreasing the structural integrity.

Plastic sewer pipes have been the common choice since the 1970s because they do not rot, rust or corrode.

Plastic PVC (poly Vinyl Chloride) or ABS (Acrylonitrile-Butadiene-Styrene) pipes are smooth, inhibiting blockages or clogs in a sewer line.

PVC, (polyvinyl chloride) pipes withstand very cold temperatures and are stronger than ABS.

ABS, (Acrylonitrile-Butadiene-Styrene) pipes are slightly more flexible than PVC pipes and are less likely to crack as the soil sets or moves.

If your home was built in the 1970s you may or may not have ABS or PVC sewer pipes.

Although plastic is the ideal material for sewer pipes, you can have leaks if the pipe joints are not sealed properly. If pipe joints are leaking, a root even the size of a hair can begin to make its home inside your sewer line.

Over time, if roots establish in the sewer line, a clog can form in the pipe. The roots act like a net catching solid waste and debris as it tries to move through the pipe. This can lead to a sewer backup.

Another concern with ABS or PVC pipes is bellies. A pipe belly is when the sewer pipe sags.

A pipe belly will collect waste and debris, causing a clog and inhibiting sewage from moving freely down the pipe.

Typically, a pipe will belly when the earth around the pipe isn’t providing enough support to the weight of the pipe.

When sewer pipes are installed, it is essential that gravel and rocks are used to support the sewer line.

Poor installation may not be the cause of a pipe belly, but could be the result of the ground shifting.

Although plastic pipes as less susceptible to failure, it is a good idea to schedule a sewer line camera inspection to ensure that your sewer line is in good working order. (link to camera inspection)