Same Day Service Since

2001

Call The Gentleman Pros Now!

(403) 879-1759

Furnaces can be confusing. There are different ways of heating, different fuels, and different terms for the same things.

There are forced-air furnaces, conventional furnaces, mid-efficiency furnaces, high-efficiency furnaces, condensing furnaces, and non-condensing furnaces to name a few. And this doesn’t even include the different add-ons you can get for your furnace.

With so many options and little consistency in what things are called, how are you to figure out what you need?

Don’t worry, this section is your Furnace 101. It contains an overview of:

This is all the background information you need to understand your furnace research and help you make the best decision.

Before we delve into all things furnaces, we’re going to give you a brief overview of the different heating systems available. Why, you ask? Because when researching your new furnace you will come across them and it is helpful to have a basic understanding of what they are.

A boiler burns a fuel source to heat water and then distributes the hot water or steam throughout your home via a series of pipes and radiators. Not very common in Canada, according to Statistics Canada. In 2019, only nine percent of Canadian homes used a boiler as their primary heating source.

Unlike boilers and furnaces, heat pumps do not generate heat. They transfer existing heat between the outside and the inside of your home using a refrigerant. When you need to heat your house, the refrigerant absorbs the heat from the outside and moves it to the indoor units which disperse the heat into your home. When you need to cool your house, the refrigerant absorbs the heat from inside your home and transfers it outside.

Transfers heat between the outside air and the home.

Transfers heat between the ground and the home.

Heat pumps usually are not an effective heating source for our cold Canadian climate and in 2019 only five percent of Canadian homes used a heat pump as their primary heating source.

This is the most common type of heating system in Canada. In 2019, 52 percent of Canadian households used one as their primary heating source.

They are referred to as furnaces, forced-air furnaces, and central furnaces. Don’t worry, they all mean the same thing. For simplicity’s sake, we will use the term furnace.

Basically, furnaces burn a fuel source to heat air and then using a fan, distribute the heated air throughout your home via ducts.

Furnaces can be powered with natural gas, propane, oil, or electricity. You will need to decide which fuel you prefer based on the fuel available in your location, the fuel source your current furnace is using, the fuel’s environmental impacts, and the fuel’s cost.

It can be expensive to switch your heating from one fuel type to another, so most people stick to the same fuel as their old furnace.

Based on the most recent information from Statistics Canada (2011), electric heating systems are the second most common system in Canada with 39 percent of households using electricity to heat their homes.

Electric furnaces:

Propane heating systems are more common in rural areas where there isn’t good access to natural gas or electricity. A propane tank is installed outside your home and connected to your heating system. You will need to have regular deliveries of propane to ensure your tank is full.

Propane furnaces:

Oil furnaces are also more common in rural areas where it is difficult to access other fuel types.

Oil furnaces:

According to the most recent information from Statistics Canada (2011), natural gas is the most common fuel to power heating systems in Canada, especially in Western Canada and Ontario. In Alberta, 91 percent of homes are heated with natural gas.

Natural gas is a safe, reliable, and readily available fuel for furnaces. Natural gas furnaces:

How a furnace works is pretty simple … in theory. It heats air and then distributes it throughout your house.

However, there are a lot of different components that have to work together for your furnace to successfully heat your house. Each component has a specific role — sometimes more than one role — in your furnace’s operation.

When selecting a new furnace, it’s helpful to have a basic understanding of these components and how they work together.

The thermostat is the control centre of the furnace. It detects the room’s temperature and if the temperature is below the preset temperature, it sends a message to the furnace to start producing heat.

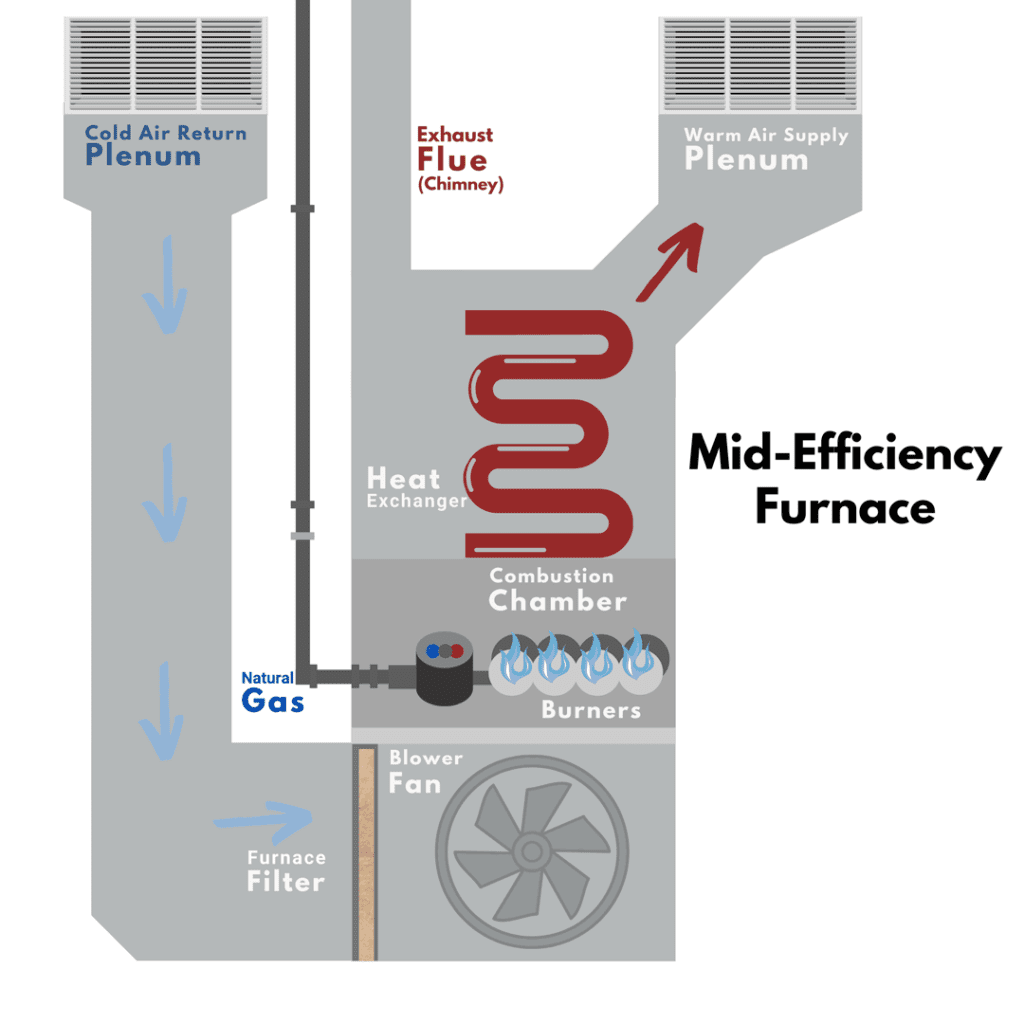

Cold air returns are a series of vents in your home and are part of the system that recycles your home’s air. They pull air from your rooms into the return ducts which deliver the air to the furnace where it is reheated and then distributed throughout your home. Once the air has cooled, the cold air returns once again pull the air to the furnace and the cycle continues.

You can tell if a vent is a cold air return by putting a piece of paper up to it when the furnace is on. If the piece of paper is pulled towards the vent, you know it’s the cold air return.

Do not block your cold air returns.

The filter screens out debris and contaminants from the air supplied to the furnace before it is heated and distributed.

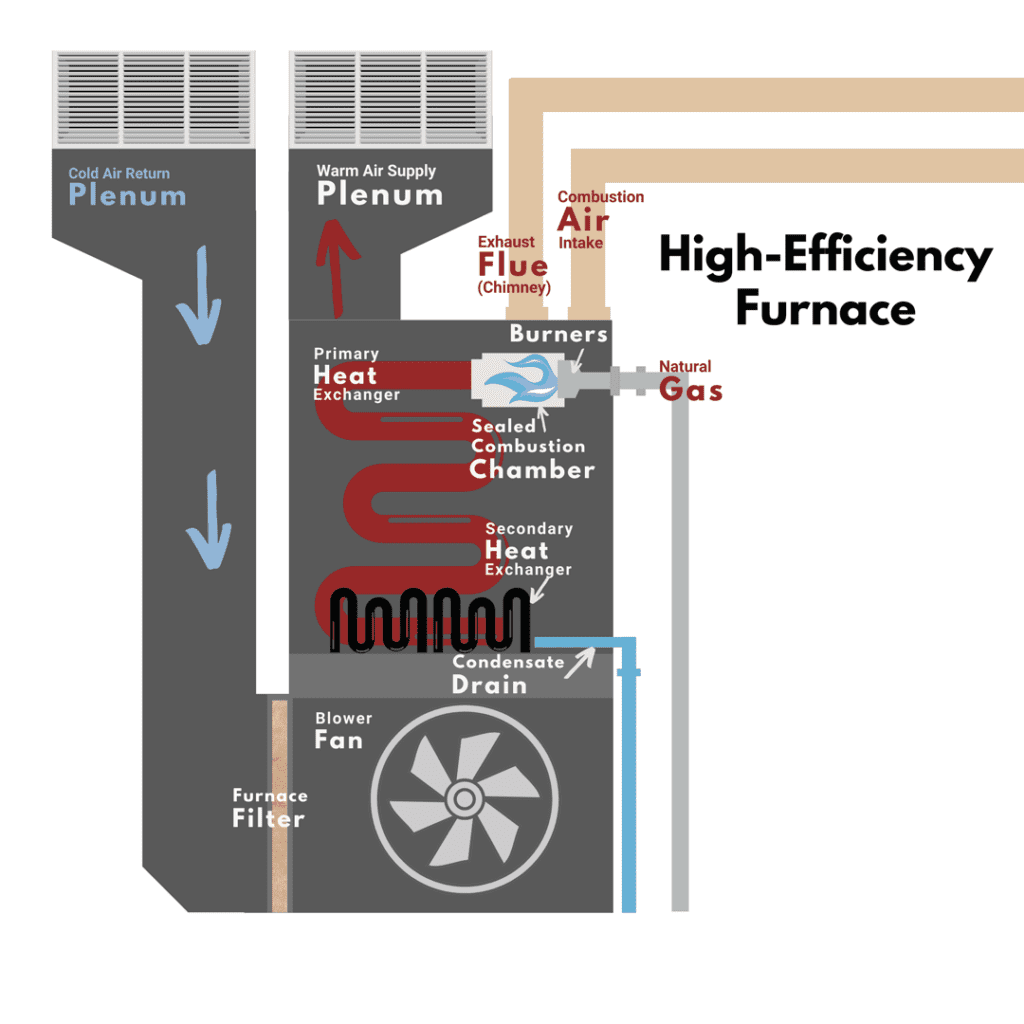

A newer component in furnaces is the draft inducer fan. All high-efficiency furnaces and some mid-efficiency furnaces have one.

The draft inducer increases a furnace’s safety and efficiency. Before the burners are lit, the draft inducer clears out any gas in the heat exchanger left from the previous heating cycle. It then continues to blow throughout the heating cycle, helping to provide the burners with a constant source of oxygen allowing the burners to burn as efficiently as possible.

The pressure switch is a safety feature that measures the amount of air being blown by the draft inducer. If it doesn’t detect enough air to sufficiently remove the exhaust gases, the pressure switch shuts down the furnace.

The flame sensor and thermocouple are safety devices that detect if the burners are working or not. If a flame isn’t detected in the burners, these devices shut off the gas so it doesn’t build up in the furnace and leak into your home.

Flame sensors are used in furnaces with an electronic ignition system.

Thermocouples are used in furnaces with a standing pilot light which is an older style ignition system.

Electronic ignition systems have replaced pilot lights. The two most common types are:

This system doesn’t use a flame to light the burners. Instead, when the thermostat tells the furnace to heat, an electric current heats up a metal probe. Once the metal probe, sometimes called a glow stick, reaches a certain temperature it ignites the burners and then the hot surface ignition turns itself off.

This system is similar to the original pilot light system. Unlike the original pilot lights, the intermittent pilot light does not always have a burning flame. When the furnace is called upon to heat, an electronic spark ignites the pilot light which lights the burners. Once the burners have been lit the pilot light turns itself off.

The gas valve delivers gas to the electronic ignition system and the burners.

The burners are where the air is mixed with gas to create a combustible fuel and then burned to generate heat.

The combustion chamber is the area in the furnace where the burners are located and where the combustion process takes place.

Mid-efficiency furnaces’ combustion chambers are unsealed. Meaning they pull warm air from your home for combustion which causes cold air to enter your home to replace the air used in combustion. This influx of cold air can make your home’s air drier and lower your home’s temperature.

All high-efficiency furnaces have a sealed combustion chamber. They generally pull air directly from the outside through an air intake pipe (vent) to use in combustion and ensure less heat loss when the burners are operating.

No air is pulled directly from the house for combustion which means unlike unsealed combustion chambers, no cold air enters your home to make up for the loss of air used in combustion.

The primary heat exchanger sits on top of the combustion chamber and has two roles.

One, the primary heat exchanger is heated by the burners and then it heats the air as the air travels across the exchanger.

Two, it keeps the combustion process separate from the air that is being heated. This is needed so carbon monoxide (a potential byproduct of the combustion process) does not enter the heated air and circulate throughout your home. If carbon monoxide enters your home, it could potentially cause carbon monoxide poisoning.

High-efficiency furnaces have a secondary heat exchanger where heat is removed from the exhaust from the combustion process. The exhaust enters the secondary heat exchanger before it is vented outside.

The secondary heat exchanger extracts any residual heat from the exhaust and uses it to heat your home. This cools the exhaust gas into a liquid called condensate which is then drained from your furnace and the remaining exhaust is vented to the outside.

The blower — also called the fan — takes the heated air and blows it into the duct system which distributes the heated air throughout your home.

The limit switch detects when the air inside the furnace has reached the required temperature and then turns on the blower to distribute the heated air. It then turns off the blower when heat is no longer required.

It is also a safety feature and will turn off the entire furnace if the furnace overheats.

The condensate drain line is a small pipe that removes the condensate produced by high-efficiency furnaces when they extract the heat from the exhaust. The drain line carries the condensate from the furnace to the condensate drain in the floor.

The flue is the pipe where the remaining cooled exhaust exits the furnace to the outdoors. Sometimes referred to as a chimney.

The ductwork is a series of ducts that the heated air travels through to reach the various areas of your home.

The plenum is the box that connects your ducts to your furnace.

All of these different parts work together to heat your home.

How do they work together? Well, that depends on if you have a mid-efficiency furnace or a high-efficiency furnace. There are also operational differences depending on the type of fuel used. Natural gas is the most common fuel in Canada, so the example below is for a furnace fired by natural gas.

Mid-efficiency furnaces are the most common furnaces in Canada. In fact, it is probably the type of furnace you currently have in your home.

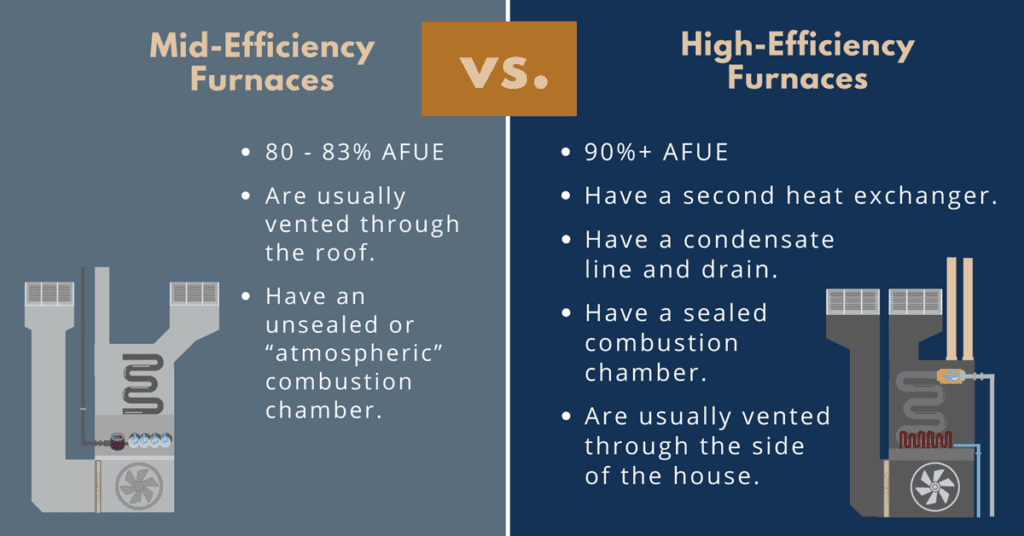

A conventional furnace — more commonly referred to as a mid-efficiency furnace — has an AFUE between 80 and 83 percent. Mid-efficiency furnaces haven’t been installed in Canada since January 1, 2010. Though, if your furnace was installed prior to that, there is a good chance it is a mid-efficiency furnace.

Mid-efficiency furnaces cannot reach higher efficiencies because they do not have a second heat exchanger to capture the heat from the exhaust gas. Instead, this heat exits your home through your chimney.

However, you can no longer buy mid-efficiency furnaces because they cannot reach the efficiency rate set by Natural Resources Canada. Any new furnace you buy will be a condensing furnace, also referred to as a high-efficiency furnace.

A condensing furnace — more commonly called a high-efficiency furnace — is the most energy-efficient furnace on the market. A high-efficiency furnace has a minimum AFUE of 90 percent.

In mid-efficiency furnaces, some of the heat produced escapes in the exhaust gas which is vented outdoors. High-efficiency furnaces have a second heat exchanger that captures this heat from the exhaust gas and uses it to heat your home.

As a result, the second heat exchanger cools the exhaust gas and some of the exhaust condenses into water. The water (condensate) drips out through a drain pipe and the remaining gases are vented through a plastic pipe to the outdoors. Other than that, it works pretty much the same as a mid-efficiency furnace.

Because high-efficiency furnaces generate more heat for heating your home with the same amount of fuel used compared to mid-efficiency furnaces, it is more energy-efficient.

To meet Canada’s natural gas furnace energy efficiency regulation, high-efficiency condensing furnaces are the only type of furnace available in the Canadian market. However, they come with a variety of different features which we will discuss next.

Both types operate similarly but high-efficiency furnaces have a few differences which allow them to reach their high-efficiency rates. High-efficiency furnaces:

The basic operating steps for both a conventional mid-efficiency furnace and a condensing high-efficiency furnace are:

Furnaces come in a variety of installation configurations with a variety of features. These are the most common ones.

Upflow Vertical Furnace

Upflow refers to where the air enters and exits the furnace and vertical refers to how the furnace is installed. An upflow vertical furnace takes cold air in at the bottom of the furnace, heats it, and distributes the heated air through the top of the furnace. It is installed vertically and is best for basement and crawl space installations.

Downflow Vertical Furnace

In a downflow vertical furnace, the cold air enters the top of the unit, is heated, and then dispersed through the bottom of the unit. It is also installed vertically. It is best suited for installation in attics and closets and tends to be less efficient than an upflow vertical furnace.

Horizontal Furnace

A horizontal furnace lays on its side and is installed in small spaces that don’t have enough room for a vertical furnace. Cold air enters one side of the unit, is heated, and dispersed through the other side. They can be hung from the ceiling or installed on a platform. These units are also less efficient than upflow furnaces.

Multi-Position Furnace

A multi-position furnace can be installed either vertically or horizontally and the airflow can be set up in either a upflow or downflow configuration (if installed vertically). They are also called multipoise furnaces, universal airflow furnaces, or multi-positional furnaces.

The configurations listed above are the most common ones, but there are other configurations available. Please consult an HVAC professional to make sure you get the best furnace for your situation.

Regardless of the airflow and manner of installation, you can purchase these furnaces in a variety of stages and speeds as outlined below. The airflow and position only refer to how air moves through the furnace and the position in which it is installed.

You will need to decide how many stages you want your furnace to have. Do you know what a furnace stage is? I didn’t, so let’s find out.

Single-Stage / One Stage Furnace

A single-stage furnace only has one heat setting — high. It is either on or off, there is nothing in between.

When it is on, it burns the maximum amount of fuel to generate heat and then circulates the maximum amount of heat it is designed for until it reaches the desired temperature, and then it shuts off.

Two-Stage / 2-Stage / Dual Stage / Double Stage Furnace

However you refer to it, it has two heating settings. A medium setting — the first stage — meets your heating needs the majority of the time. And a high setting — the second stage — kicks in when it is really cold outside and provides the additional capacity needed to reach your thermostat’s temperature setting.

Two-stage furnaces are more efficient than single-stage furnaces because they are not always operating at their maximum and as a result burn less fuel. Keep in mind this increased efficiency is not included in the AFUE rating.

Be aware, some will refer to a two-stage furnace as a multi-stage furnace. While this is technically true — two is multiple stages — it is misleading because it doesn’t have all the benefits as the furnaces discussed next.

Modulating Furnace / Multi-Stage Furnace

A modulating furnace provides more consistent heat than other furnaces because it responds in smaller increments to a change in your home’s temperature. It does this by subtly adjusting the amount of fuel burned. With a modulating furnace, your home’s temperature rarely fluctuates more than a few degrees from your thermostat’s setting.

A modulating furnace is more efficient than a single-stage or two-stage furnace because it minimizes overheating and uses less fuel. As mentioned earlier, this increased efficiency is not included in the AFUE rating.

Variable Speed Furnace / Multi-Speed Furnace

Variable speed refers to the type of blower motor — fan motor— in your furnace. Variable-speed furnaces contain an electronically commutated motor (ECM).

An ECM is more efficient than other blower motors because it can adjust its speed in much smaller increments controlling the speed at which the heated air is being dispersed throughout your home. As with multiple stages, this added efficiency is not included in the AFUE rating.

A variable speed furnace produces better airflow meaning a more consistently heated and comfortable home.

Non-Communicating vs. Communicating Furnaces

Non-communicating and communicating refer to how the different components in a furnace “talk” to each other. With both systems, you need to ensure the thermostat is compatible with that specific type of furnace.

Non-Communicating Furnace

Non-communicating systems are used in single-stage and two-stage furnaces.

The thermostat has a wire running to each component which allows it to issue one of two instructions to the furnace or required component — either on or off. It does this by altering the path of the electricity — called a circuit — from the thermostat to the furnace or the component it needs to operate.

Communicating Furnace

A communicating system is used with some two-stage furnaces and all modulating furnaces and operates more like a computer network.

Each component has its own electronic address and pairs with the thermostat in a manner similar to Bluetooth.

Each component continuously informs the thermostat of its existing operating capacity. The thermostat can then precisely adjust each component’s output ensuring the furnace functions optimally.

If installed and set up properly, these furnaces are more efficient and have lower operating costs than their non-communicating counterparts. They also provide more consistent room temperatures and are quieter. They can even diagnose issues and alert the homeowner when minor maintenance is needed.

However, there are tradeoffs. These systems are more expensive to buy, maintain, and repair, troubleshooting can be difficult, and many technicians don’t have the experience to properly install and set up these systems.

For more information on non-communicating and communicating furnaces, check out this.